DONGYUAN matt metal flower sculpture manufacturers for square

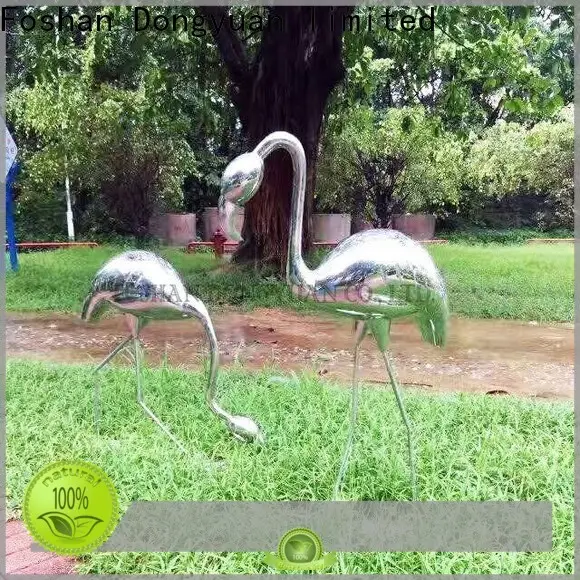

Stainless Steel Cranes

Step 1: Molding

For custom metal art sculptures, a mold will be presented first so that a sculpture will draw and improve on later. On the basis of the complexity of it, there are various types of molds available, including clay, plastic and foam etc. However, as to stainless steel cranes, we will usually use foam to make a mold, since it is more flexible. Still, a made could be modified for several times before we actually start manufacturing.

Step 2: Preparation

To produce stainless steel animals, for example, cranes or penguins, we should first calculate stainless steel sheet. By using the mold in the Step 1, stainless steel plane will be cut and bent to the shape of a crane or penguin by parts which will be pieced together and welded then. Eventually, we will have a crane of stainless steel.

Step 3: Hammering

With a hammer, professional workers will slowly and patiently hammer at it so that it could gradually be as identical as the shape of the mold.

Step 4: Polishing

After hammering, it will be polished for several times and cleaned by using polishing machine and polishing wax. In this Step, workers will use a glazing machine gently and thoroughly on the surface. They are also required to use different sizes of machine on different parts of the crane.