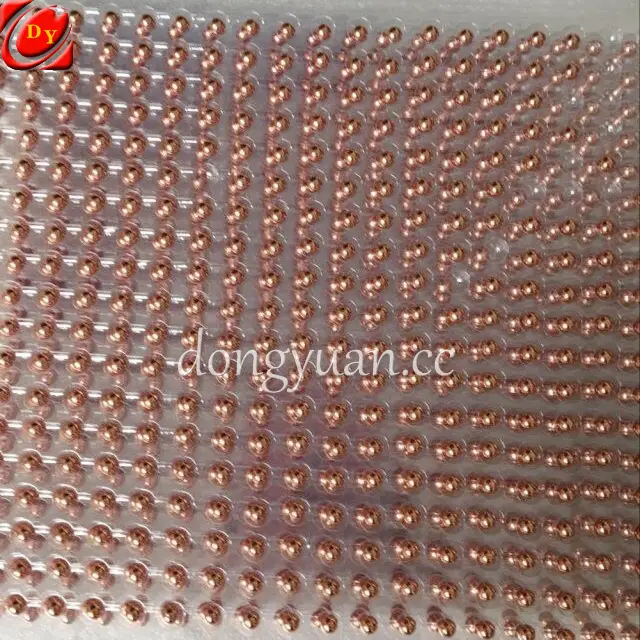

99.99% Cu Purity 12mm Copper Balls with Drilled Holes

We are capable of providing stainless steel spheres/balls almost as per your specific requirements. Products include hollow stainless steel spheres (ranging from 6mm to 2500mm in diameter), available for delivery if we have it in stock or delivered within 15 days. Wall thickness of spheres varies from 0.4mm to 3mm. Shaped by water pressure, our products could be mirror polished without any seams noticeable on the surface; meanwhile, welding and then sandblasting spheres is a another way to produce mirror polished spheres also without detectable traces on the spheres. Having been offering services for our customers worldwide, a variety of products also fall under many categories of our products. Staidness steel spheres, hollow or solid, of all sizes are our major products, and brass and bronze balls come along. Hollow reflective stainless steel spheres of enormous sizes are amongst the top sales in our products. Perforated stainless steel spheres or sculptures of 304 or 316 are also our hot products. Not to mention we have done considerable amount of drilled stainless steel balls or spheres with holes of many sizes. Our products are of professional and advanced technology with cost-effective craftmanship and favorable delivery time.

Do you customize?

--Yes, the majority of our business is either using our in-house designs, or further developing your own designs presented to us. We can modify by re-scaling, re-sizing, adding signage / script etc.

Can I choose a specific rust color or pattern?

--Each product has its own unique character and finish. The color variations are part of the intentional design and, being an organic process, it cannot be controlled.

What is the weight?

--It depends on the subject products. If it is a standard size sphere, then it would be easy for us to give you an estimate weight regardless of the error or deviation. If it is a customized product, all designs vary according to intricacy and negative/positive space, and if framing is necessary.

What is your delivery process?

-- Local deliveries are notified before dispatch to confirm a suitable delivery time slot. Rural, interstate & international deliveries are dispatched using express or sea transportation as per our client’s request .

Copper is a reddish coloured metal which is malleable and ductile. It has excellent thermal and electrical conductivities and good corrosion resistance. It is found in sulphide ores and as carbonate, arsenide and chloride (abundance in the Earth's crust is 50 ppm). Extraction of the metal involves roasting the ore to produce the oxide, followed by reduction and purification by electrolysis. The element is inert to non-oxidising acids but reacts with oxidising agents. In air, it will weather to produce the characteristic green patina of the carbonate. Copper will combine with oxygen on heating to produce CuO at red heat, and Cu2O at elevated temperatures.

Pure copper has an electrical conductivity second only to that of silver and hence its main application is in the electrical industry. Copper is also the basis of many important alloys (e.g. brass, bronze and aluminium bronze) and has been traditionally considered to be one of the coinage metals, along with silver and gold, but being more common, is the least valued. It is one of the first metals ever to have been worked by man and is thought to have been mined for more than 5000 years.

Environmental effects of copper

When copper ends up in soil it strongly attaches to organic matter and minerals. As a result it does not travel very far after release and it hardly ever enters groundwater. In surface water copper can travel great distances, either suspended on sludge particles or as free ions.

Copper does not break down in the environment and because of that it can accumulate in plants and animals when it is found in soils. On copper-rich soils only a limited number of plants has a chance of survival. That is why there is not much plant diversity near copper-disposing factories. Due to the effects upon plants copper is a serious threat to the productions of farmlands. Copper can seriously influence the proceedings of certain farmlands, depending upon the acidity of the soil and the presence of organic matter. Despite of this, copper-containing manures are still applied.

Copper can interrupt the activity in soils, as it negatively influences the activity of microorganisms and earthworms. The decomposition of organic matter may seriously slow down because of this.

When the soils of farmland are polluted with copper, animals will absorb concentrations that are damaging to their health. Mainly sheep suffer a great deal from copper poisoning, because the effects of copper are manifesting at fairly low concentrations.

Product name | Red copper balls | ||||||

Diameter | φ1.0mm—φ42mm,,, Hollow : 6mm to 200mm | ||||||

Applications | Valves, spray, instrument, pressure gauge, water meter, carburetor, electrical accessories, etc | ||||||

| Cu | Pb | P | Fe | Zn | So | Bi |

99.7-99.9% | 0.005% | --- | 0.005% | 0.005% | 0.002% | 0.002% | |

Class | Copper (%) | Zinc (%) | Notes |

Alpha brasses | >65 | <35 | Alpha brasses are malleable, can be worked cold, and are used in pressing, forging, or similar applications. They contain only one phase, with face-centered cubic crystal structure. |

Alpha-beta brasses | 55–65 | 35–45 | Also called duplex brasses. Suited for hot working. It contains both α and β' phase; the β'-phase is body-centered cubic and is harder and stronger than α. Alpha-beta brasses are usually worked hot. |

Beta brasses | 50–55 | 45–50 | Can only be worked hot, and are harder, stronger, and suitable for casting. |

White brass | <50 | >50 | Too brittle for general use. The term may also refer to certain types of nickel silver alloys as well as Cu-Zn-Sn alloys with high proportions (typically 40%+) of tin and/or zinc, as well as predominantly zinc casting alloys with copper additive. |

Group Number Chemical composition,%(weight)

Name Number Cu+Ag P Bi Sb As Fe Ni Pb Sn S Zn O

Oxygen free copper NO.2 TU2 max 99.95 — — — — — — — — — — —

Oxygen free copper min — 0.002 0.001 0.002 0.002 0.004 0.002 0.004 0.002 0.004 0.003 0.003

Pure copper No.2 T2 max 99.90 — — — — — — — — — — —

Copper min — — 0.001 0.002 0.002 0.005 — 0.005 — 0.005 — —

No.3 T3 max 99.70 — — — — — — — — — — —

Copper min — — 0.002 — — — — 0.01 — — — —

Deoxidized phosphorus copper No.1 TP1 max 99.90 0.004 — — — — — — — — — —

Deoxidized phosphorus copper [C12000] min — 0.012

No.2 TP2 max 99.90 0.015 — — — — — — — — — —

ASTM B134-52 Alloy 7 brass

hemical Analysis:

Copper............................................68.5% to 78.5%

Lead.................................................0.07% maximum

Iron...................................................0.05% maximum

Zinc..................................................Balance

Mechanical Properties

Hardness as measured on parallel flat surfaces is Rockwell “B” 75 to 85.

Tensile Strength............................80,000 psi

Yield Strength................................57,000 psi

Elongation in two inches.............20%

Reduction in area.........................85%

Modulus of elasticity....................15,000,000 psi

Density...........................................0.306 lbs./cu. in.